Japan Display (JDI), which is in debt, has developed the next-generation display "micro LED" (micro LED) and "transparent liquid crystal". Among these, the "transparent liquid crystal" is characterized by a transmittance of 87%, and we are aiming for mass production in 2020.

"Micro LED" that does not deteriorate from organic EL

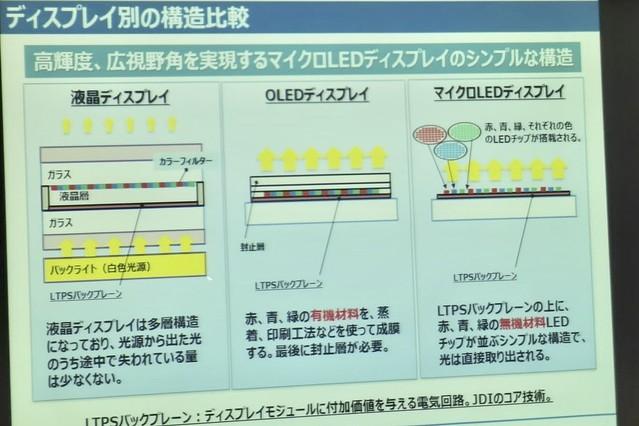

The "micro LED" display developed by JDI has a 1.6-inch 300 x 300 resolution and can be enlarged to about 10 inches. By laying 270,000 fine LED chips per 1.6 inches on the LTPS backplane, a high pixel density of 265ppi is achieved.

▲ The display is 1.6 inches (265ppi), but it can be enlarged to about 10 inches. Sony also commercializes this "micro LED" as "CrystalDisplay" for large screens, but JDI's panel is mainly For small and medium size. Since the pixel density per inch is also high, the difference is that it can be applied to mobile devices such as smartphones. The advantages compared to existing displays are "durability" and "high brightness". In the case of organic EL, organic materials are used for the pixels, so they deteriorate easily when exposed to air. In order to deal with such deterioration, existing organic EL displays have a "sealing layer" that keeps the organic EL from the outside air, but "micro LEDs" that use inorganic materials do not require a sealing layer. It can be used stably even in harsher environments. It also features a brightness of 3000cd/m2, which is 10 times higher than a typical LCD display. The person in charge says, ``We will achieve a display that is resistant to direct sunlight,'' and we are exploring applications mainly for in-vehicle applications. Regarding the installation in smartphones, he said, ``It is possible if the value is accepted because it is characterized by high brightness.''

▲Although it is intended for use in in-vehicle displays due to its "high brightness" feature, it can also be installed in smartphones. Micro LED chips procured from glo in Silicon Valley

▲ Unlike organic EL, it does not use organic materials, so it is resistant to deterioration.Although mass production technology has been established, the timing of mass production is undecided. The manufacturing cost does not match that of already established panel technologies such as liquid crystal and organic EL. In order to reduce the price, it is essential to spread it to the mass market, and the investment scale can be reduced compared to organic EL, etc., because the "LTPS backplane" used in liquid crystals can be used as it is in manufacturing. ] and showed recognition.

Transparent liquid crystal will start mass production in 2020

The other display is a 12.3-inch transparent liquid crystal display. In 2017, JDI developed a 4-inch display that adopted technology to remove the color filters and polarizing plates required for conventional liquid crystal displays. This time we made it bigger.

▲Colors are crazy in the picture, but the actual display is clear

▲ Transparent displays that are transparent even when viewed from the back side are not uncommon, as manufacturers have already developed them, but JDI's has achieved a world-class non-display transmittance of 87%. The resolution is 1440 x 540. It is said that the transparent liquid crystal is not for viewing beautiful images and images, so the maximum display capacity is limited to 4096 colors. It also does not support touch functionality. This transparent liquid crystal is scheduled to be mass-produced in 2020. As a specific use case, we are envisioning information display on transparent glass that separates staff and customers at ticket offices. In addition to that, we are proposing "how to use a new display with a sense of the future".

▲ JDI, which proposes a futuristic display usage, has started manufacturing organic EL displays for Apple Watch in Mobara City, Chiba Prefecture. In addition, we would like to show off our technological capabilities and make a comeback by showing off next-generation display technologies such as "transparent displays" and "micro LEDs."